What is the ORACLE Fuel Flow Analyzer System?

Able to detect issues with the fuel delivery

systems; have you ever had a driveability issue, as

in low or no power, engine power issues

after 35 MPH (45KPH), slow response and no

DTC/Codes and good fuel pressure

to top all off?

Well then, what to do next?

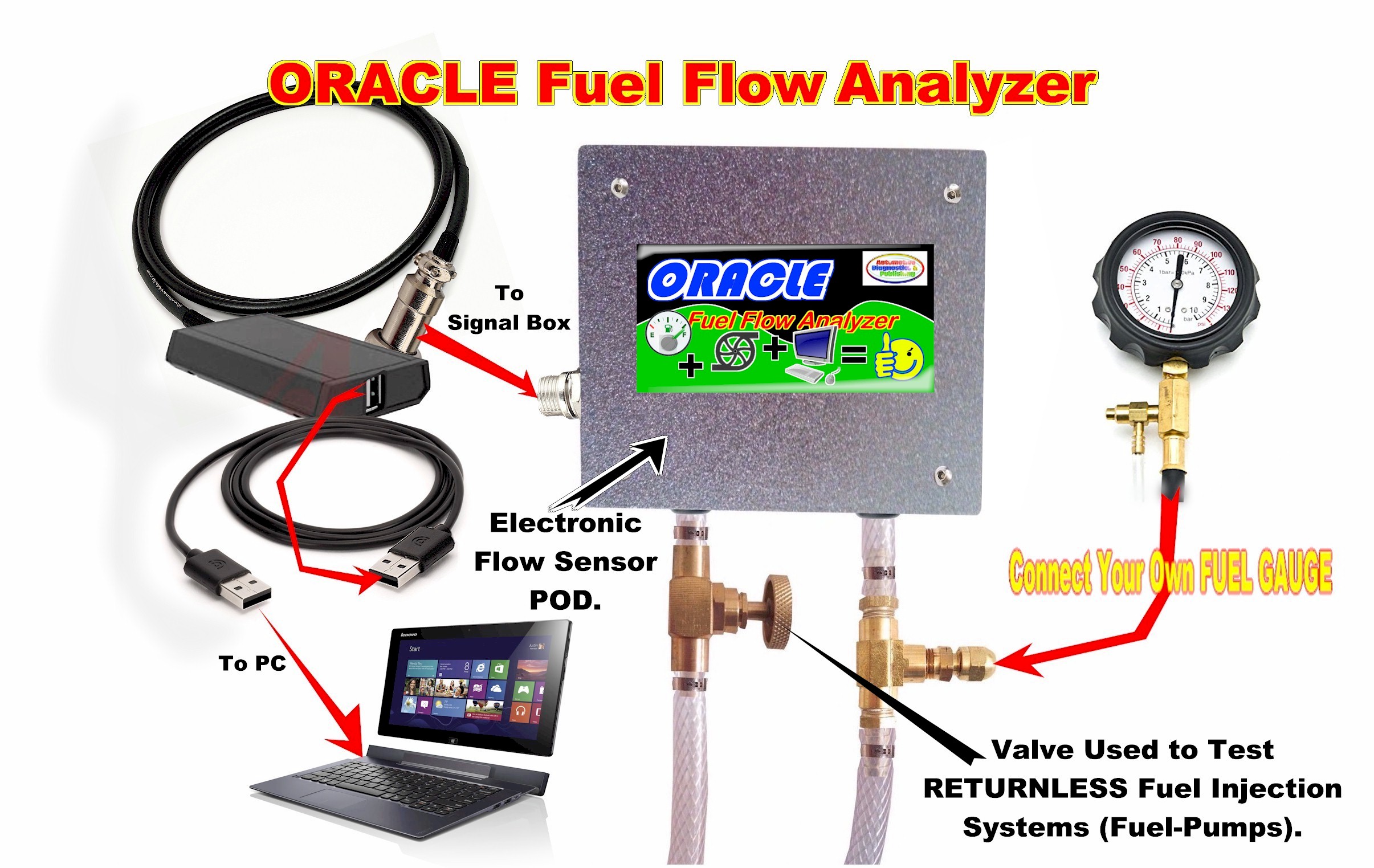

The ORACLE Fuel Flow Analyzer System is a PC

based/USB diagnostic equipment connected in-line

with the fuel hose outlet. In fact, it is connected

in series with the fuel line, so all the fuel first

flows through the ORACLE then to the engine. The

ORACLE'S turbine sensor is a state of the art, tough

sensor, that also connects to the electronic

interface to the PC/Computer (Windows Based XP, 7, 8

and 10). It also comes with a set of fuel line

adapters to make it possible to connect the ORACLE,

in-line or in-series with the fuel system.

The second part of the ORACLE Fuel Flow Analyzer is

the "SOFTWARE" (future updates included). The ORACLE

Software is PC based and was custom made and

developed for the ORACLE. So, this is an automotive

fuel flow analyzer made from the ground up to work

with cars. Able to detect subtle changes in fuel

flow, such as "Active or Dynamic Fuel Injector

Operation" depending on the demands of

conditions to the engine. This is the tool to

use when everything else failed. When the

scanner has no-codes; when you've thrown

a few parts at the vehicle in desperation;

when you know the ignition and engine mechanical

is fine; that's when the ORACLE is needed.

Why the ORACLE; to do what?

The issue is that fuel delivery relies on two

aspects: Fuel Pressure and Fuel Volume. In faulty

cases before mentioned, the pressure stays correct

and rock solid, unless the issue is severe,

then you start loosing pressure. Issues with the

fuel pump non-operational, there's no need for the

ORACLE; just replace the fuel pump.

The ORACLE was designed to detect specific fuel

conditions (flow) at certain engine LOADS. This is

undetectable by the ECM/Scanner or any other means,

so no CODES. It is often detected using an

oscilloscope; but this is difficult to do and in

many cases time consuming, more so than connecting

the ORACLE.

The ORACLE is able to detect fuel flow faults as low

as 0.05 gallons per minute. Keep in mind that all

engines, be it 4, 6, 8 or 12 cylinders need at least

0.3 gallons per minute to operate at idle. By

knowing the "Maximum Fuel Pump Delivery Rate",

you are able to properly diagnose these types of

problems. Also, the issue may not even be the fuel

pump, but injectors, fuel lines and even certain

sensors that block fuel delivery to the engine

causing these low power driveability issues. The

ORACLE also has a useful manual needle valve to "Test

Fuel Pump Maximum Flow" on Returnless Fuel

Systems, which are extremely tough the test.

With the ORACLE, it's very simple to do.